Wieland Small Tube Products – Precision You Can Trust

Our Commitment to Quality Starts at the Core

At Wieland Small Tube Products (WSTP), quality isn’t just a final inspection step; it’s built into every tube we produce. From raw material selection to final delivery, we implement rigorous quality control protocols to ensure every product meets the highest performance, compliance, and consistency standards.

We serve demanding industries, and we know failure is not an option. That’s why quality is so important. We test, we certify, and we deliver with confidence.

Request a Quote

ISO 9001 Registered

WSTP’s ISO 9001:2015 registration reflects our robust quality management system, process consistency, and customer-focused continuous improvement. Our entire facility maintains this registration ensuring that regardless of application, quality remains our top priority.

ISO 17025 Accredited Laboratory

WSTP’s ISO 17025-accredited test lab further ensures our products are being tested and certified to meet the requirements of our customers. This additional accreditation further solidifies our commitment to high quality standards in everything we do. Check out our Scope of Accreditation to understand which product tests are covered by this accreditation.

Our ISO 17025-accredited lab offers:

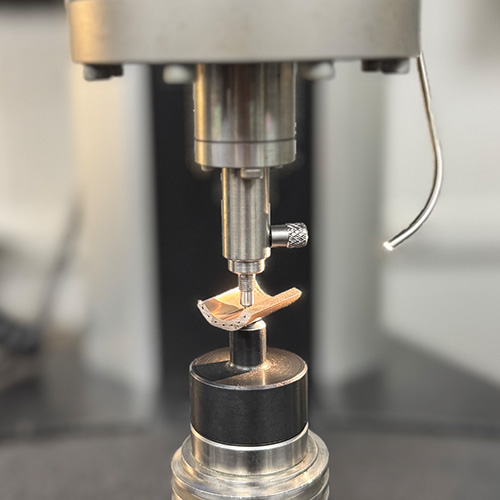

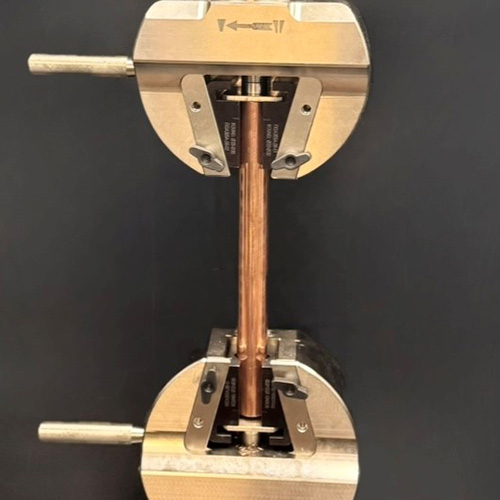

- Advanced mechanical and physical testing.

- Testing services available for both in-house and third-party tubing products.

- Certification options, including Blanket Certifications, Certificate of Compliance, and Full Certification Reports.

Quality isn’t just a goal—it’s our standard.