Welcome to

Wieland Small Tube Products

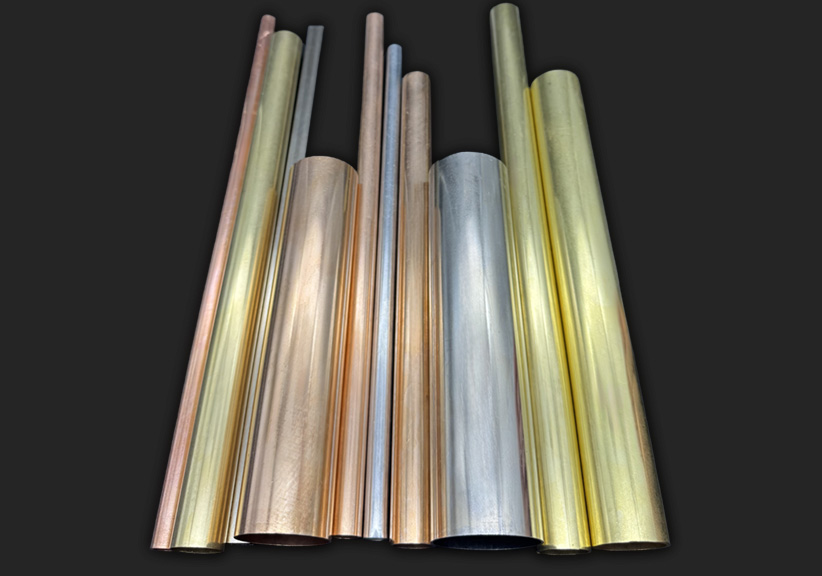

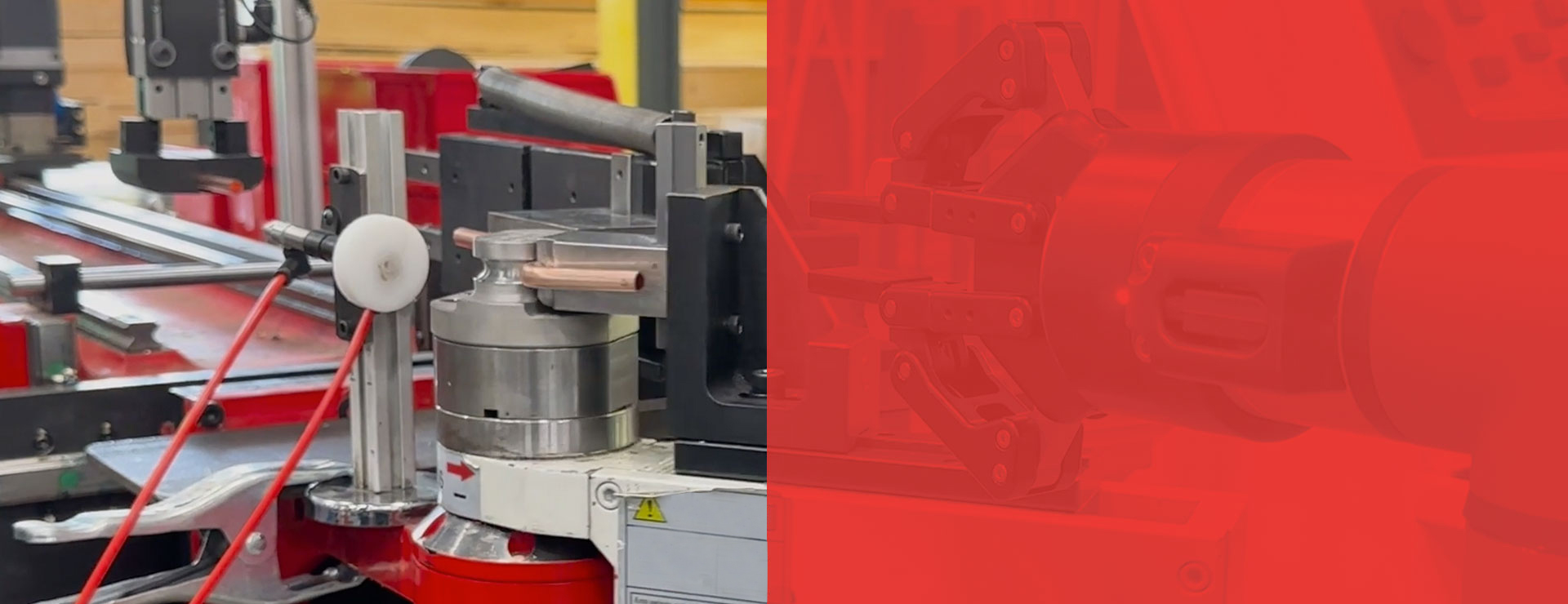

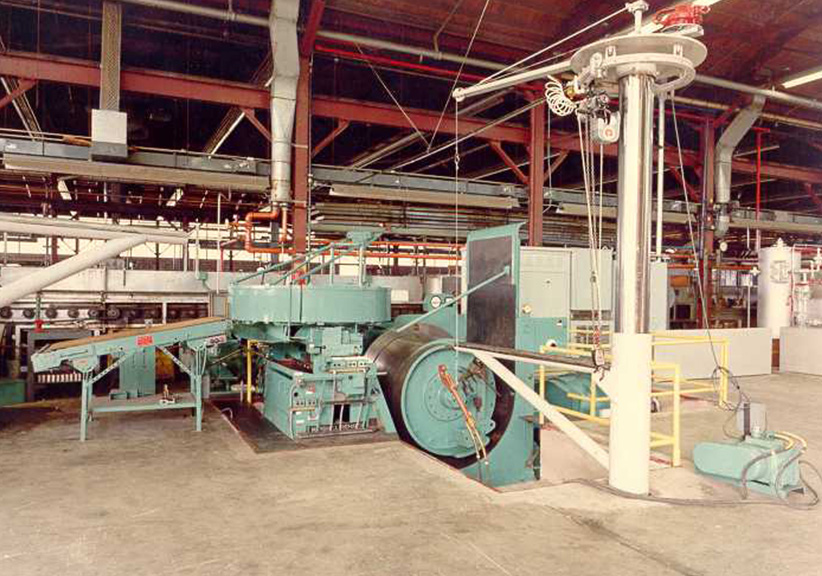

Wieland Small Tube Products (WSTP) is a copper and aluminum alloy tube mill which has been serving customers for over 75 years. A subsidiary of the Wieland Group, our USA-based company operates as a make-to-order mill producing standard and custom size tube (copper, brass, bronze, copper-nickel, nickel-silver and aluminum) and tube fabrications.