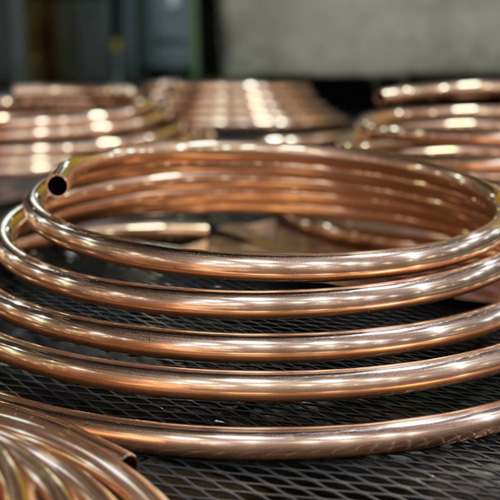

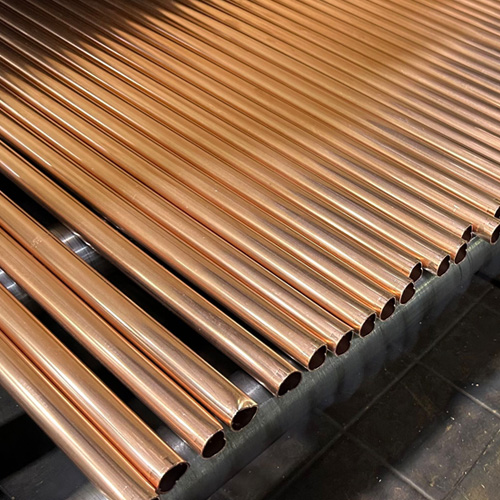

Temper Capabilities for Copper and Aluminum Tubes

At Wieland Small Tube Products (WSTP), we specialize in delivering precision-engineered copper and aluminum tubing tailored to meet your specific requirements. One of our core competencies is providing a wide range of temper options, from heavy anneal to full-hard conditions. These temper offerings allow us to provide optimal formability based on the customers’ unique applications.

Request a Quote

What Is Temper?

Temper refers to the hardness of a material. In copper and aluminum alloys, the temper is determined by:

- Softness: Achieved through annealing (controlled temperature and time).

- Hardness: Achieved through cold work reduction (controlled deformation of tube).

While annealing can produce a softened tube, varying degrees of hardness—ranging from quarter-hard to full-hard conditions—are achieved through controlled cold reduction. This process enables us to provide a wide spectrum of temper options to meet diverse customer needs.