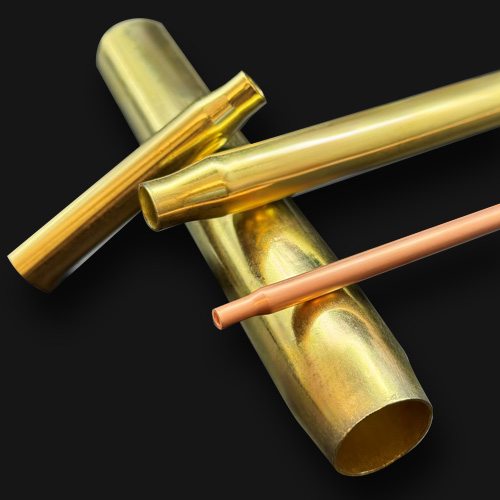

Custom Copper & Aluminum Alloy Solutions

Precision Tubing for Critical Applications

At Wieland Small Tube Products , we engineer custom copper and aluminum tubing solutions to meet the demands of highly specialized industries. With advanced manufacturing capabilities and decades of metallurgical expertise, we help you achieve performance, precision, and reliability at every level of production.

No challenge is too big—or too small. From micro components to industrial-scale systems, we customize tubing to fit your exact requirements.

Trusted by Industry Leaders

We proudly serve a diverse range of industries with precision-engineered tubing built to perform under pressure:

- Heat Transfer Applications: Single and double wall tubing used in shell and tube heat exchangers and commercial boilers.

- Electrical & Electronics: Conductive and formable alloys for power transfer components.

- Welding: Mig tips, nozzles, torch handles, burning torch tips, and gas lines.

- HVAC & Refrigeration: High-efficiency thermal conductivity and corrosion-resistant alloys for coils, condensers, and chillers.

- Industrial & Automation: Custom lengths and forms for fluid systems, robotics, and heavy-duty equipment.

- Marine & Offshore: Saltwater-resistant copper-nickel tubing designed for cooling systems, desalination, and propulsion.

- Aerospace & Defense: Lightweight, strong materials for mission-critical systems that demand strength and conductivity.

- Medical & Life Sciences: High-purity, tight-tolerance tubing ideal for medical devices, diagnostics, and surgical applications.

- Consumer Products: Cable connectors, musical instruments, decorative art, jewelry, and other fabricated products.

Full Alloy Portfolio for Performance-Critical Applications

We offer one of the industry’s broadest selections of copper and aluminum alloys to ensure the right match for your application—whether you need high conductivity, corrosion resistance, strength, or machinability.

Copper Alloys Available

- C10100 – Oxygen-Free Electronic Copper (OFEC)

- C10200 – Oxygen-Free Copper (OFE)

- C12000 – Phosphorized, Low Residual Copper

- C12200 – DHP Copper (Deoxidized, High Phosphorus)

- C19400* – High-Strength Copper Alloy

- C22000 – Commercial Bronze

- C23000 – Red Brass

- C26000 – Cartridge Brass

- C27000* – Yellow Brass

- C33000 – Low-Leaded Brass

- C43500* – High-Leaded Brass

- C44300 – Admiralty Brass

- C51000 – Phosphor Bronze

- C52100 – Tin Bronze

- C68700* – Aluminum Brass

- C70600 – Copper-Nickel 90/10

- C71000* – Nickel Silver

- C71500 – Copper-Nickel 70/30

- C75200 – Nickel Silver

Aluminum Alloys Available

- A91100 – Commercially Pure Aluminum

- A93003 – Manganese Alloyed Aluminum (3003 Series)

*Select alloys are available by special order based on application and production requirements. Please consult our technical team for feasibility.

Built Around Your Needs

With our advanced drawing, straightening, and cutting equipment, in-house tooling, and strict quality control, we tailor every order to your specifications:

- Precision drawing to tight tolerances

- Exceptional straightening capabilities

- Custom-cut tubing (short or long lengths)

- Hollow profiles and non-standard shapes

- Coiled or straight form delivery

- Deburred, chamfered, or specialty-finished ends

- Value-added fabricated products

- Clean, inspected, and packaged per your standards

We accommodate both prototype development and full production runs.

Expertise

With 75+ years in copper tube manufacturing, Wieland delivers trusted, high-performance solutions across industries.

Product Range

Offers custom copper and aluminum tubing for applications like jewelry, medical devices, and refrigeration.

Quality Assurance

ISO 9001 certified with an ISO 17025-accredited lab for top-tier precision and durability.

Customer Focus

Collaborates closely with clients to create efficient, reliable, and cost-effective tubing solutions.

Let’s Build Something Better Together

For companies that demand quality and precision, Wieland Small Tube Products delivers solutions that perform. Whether you’re sourcing for product development or scaling up for full production, we’re ready to meet your specs—exactly.

Contact:Jonas Bequeath or Elizabeth Malone