Wieland Small Tube Products – Who We Are

Decades of Precision. Powered by People. Focused on You.

At Wieland Small Tube Products, excellence isn’t just what we do—it’s who we are. With a legacy dating back to 1947, we’ve grown into North America’s leading manufacturer of precision-engineered copper and aluminum alloy tubing. From our advanced facility in Duncansville, Pennsylvania, our experienced team, strong leadership, and personalized service come together to deliver unmatched quality and support. Whether you’re connecting with our expert sales representatives, getting help from our dedicated customer service team, or learning about our history and leadership, this is where precision meets people. Welcome to Wieland Small Tube Products.

Our History

A legacy of copper tubing excellence; since 1947, built on precision, innovation, and customer focus.

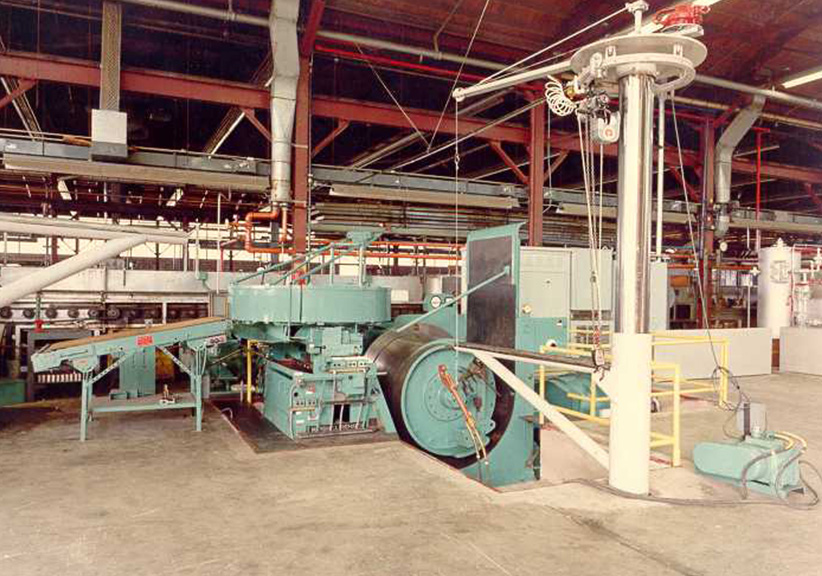

Location & Facility

Skilled people, smart location, and top-tier facilities; precision copper tubing starts here in PA.

Leadership Team

Meet the leaders driving quality, innovation, and customer success at Wieland Small Tube Products. .

Sales Team

Connect with your regional sales expert for tailored copper solutions and personalized project support.

Customer Service

Real people, real support—our customer service team is here to help you every step of the way.

Contact Us for Quality Solutions

Partner with an Industry Leader in Non-Ferrous Metal Tubing

Whether you need standard or custom tubing solutions, our team is ready to assist. Contact us today to discuss your requirements and discover how Wieland Small Tube Products can support your business.

Find Your Sales Rep